Chip making is a world in itself with its own rules, and although the chips that we use in our materials are manufactured in these foundries, it is these rules that end up influencing the design specifications of companies such as Intel, NVIDIA, AMD, Samsung, etc.

BKM or How Manufacturing Nodes Continually Improve

When a foundry use the slogan BKM, acronyms which mean “Best known method“And which is translated into Spanish as” the best known method “, these refer to the fact that although they use a specific manufacturing node, they are looking to launch an improved version, in other words , it refers to that the factory knows that the process it is currently using can be improved, but is that it is operational right now until the improved version has been developed and is ready for mass production.

It should be taken into account that foundries want to improve their manufacturing processes, for several reasons:

- Increase the production level, the number of wafers they can craft.

- Reduce manufacturing costs, not only to increase margins but also the price of wafers to be able to attract more customers or if it is your own foundry, have more competitive prices.

- Reduce the density of defects.

These three points are important in the midst of the fierce war when it comes to finding customers who need a factory for their chips and cost is the most important part.

The density of faults and their relation to the cost of manufacturing the chips

The costs associated with manufacturing the chips can be grouped into two different categories:

- Fixed costs: are the associated costs that do not depend on manufacturing, such as economic taxes on production, cost of building factories, cost of finding new nodes, cost of workers during research, etc. The cost of developing future production nodes is charged against the production cost of current production nodes. So, for example, TSMC’s 7nm wafers pay the costs of developing and deploying 5nm wafers.

- Variable costs: they depend on the number of chips produced, and this is where optimizations occur to develop new and improved variants of each manufacturing node.

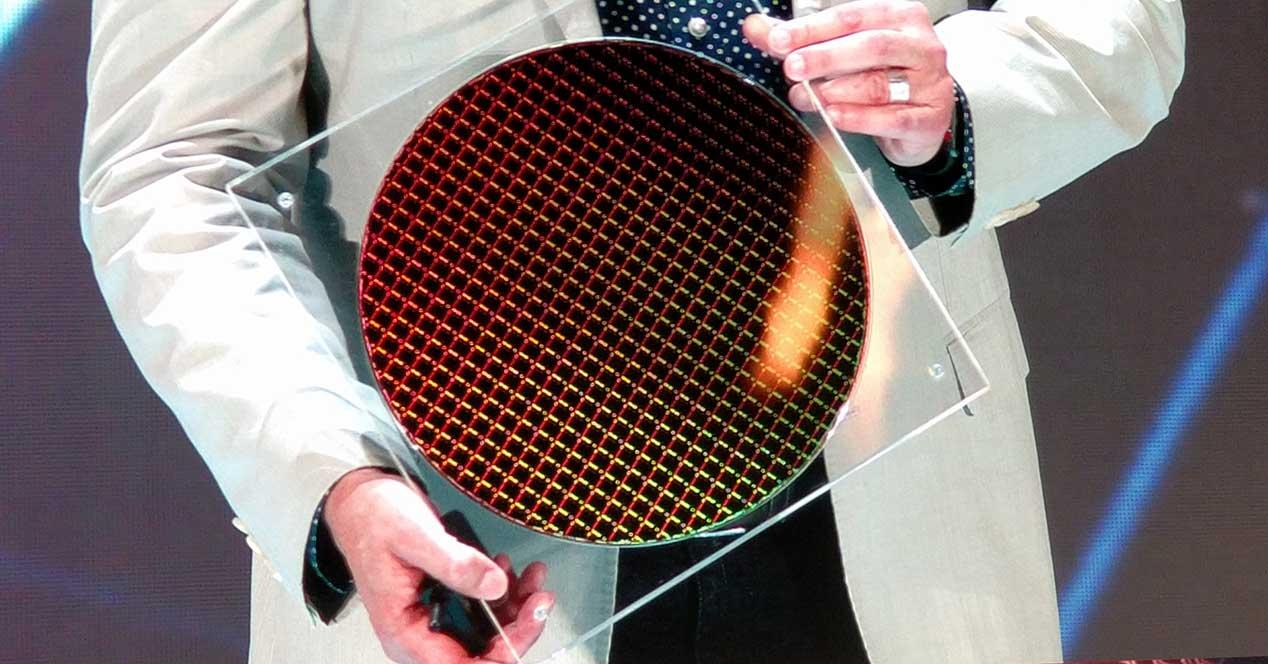

The cost of the chips depends on the volume of production, as part of the final cost depends on the number of good chips that come out per wafer, which we can represent as: cost of the wafer divided by the number of good chips that come out per wafer drives the cost of each chip.

This is obviously a simplification, because a series of defects tend to appear in the wafers which make the quantity of good chips per wafer lower than that which would be obtained in theory, the worst being those which end up loading an entire chip because randomly they affected a part which, when deactivated, forces the chip to be completely rejected.

In other cases, however, these failures do not kill the chip and therefore can be recycled as variants of the same chip with less capacity, usually as a smaller number of cores or less. cache memory.

BKM affects chip lithography

Lithography is the method used to print the chips on a wafer, in which the chips are not distributed over it in a haphazard and inconsistent manner, but their distribution is very important in order to achieve the highest possible production.

When designing a chip, within the same architecture, we can even find disparate distributions of components between two products of the same family, all this to obtain the ideal BKM when manufacturing a specific chip. .

When a chip factory develops a new variant of one of its manufacturing nodes, the distribution of lithography on the chips changes to better take advantage of improvements or a new chip design is made, with the same specifications, but with a better and more adequate distribution of the components inside the chip in order to take advantage of the new variant of the manufacturing process.

In the end, the goal is always to increase the number of good chips per wafer, reduce costs and have a more competitive manufacturing process in the market in order to attract customers.