Depending on the make and model of the radiator, one can find a great variety in terms of the arrangement of the aluminum fins: there are flat or welded fins in the shape of a honeycomb, with little or widely separated from each other and, of course, of different thicknesses. Which is the best to have a better performance?

Here’s how radiator fin spacing affects performance

The answer to the question of how it affects performance is that it depends on several factors, and the most important of all is external. It doesn’t matter if the fins are closer or further apart or even if they have the shape honeycomb

Let’s get into the situation and imagine a radiator with the aluminum fins quite far apart; in this case, the air will flow quite freely between them, so we would need a fan capable of pushing a lot of air, giving priority to the flow front to static pressure. Otherwise, where a radiator has the aluminum fins very close together, it will just need the opposite: a fan in which static pressure prevails over the airflow that it is able to move.

Indeed, since the fins are separated, the fan encounters few obstacles when it comes to pushing the air through them, so that the static pressure is not too high and the flow rate is, so that the fan can easily “fill” the spaces between the radiator fins with air. On the contrary, if the fins are too close together, the fan will find more “walls” (which depend on the thickness of the blades) and will have to have more. Static pressure

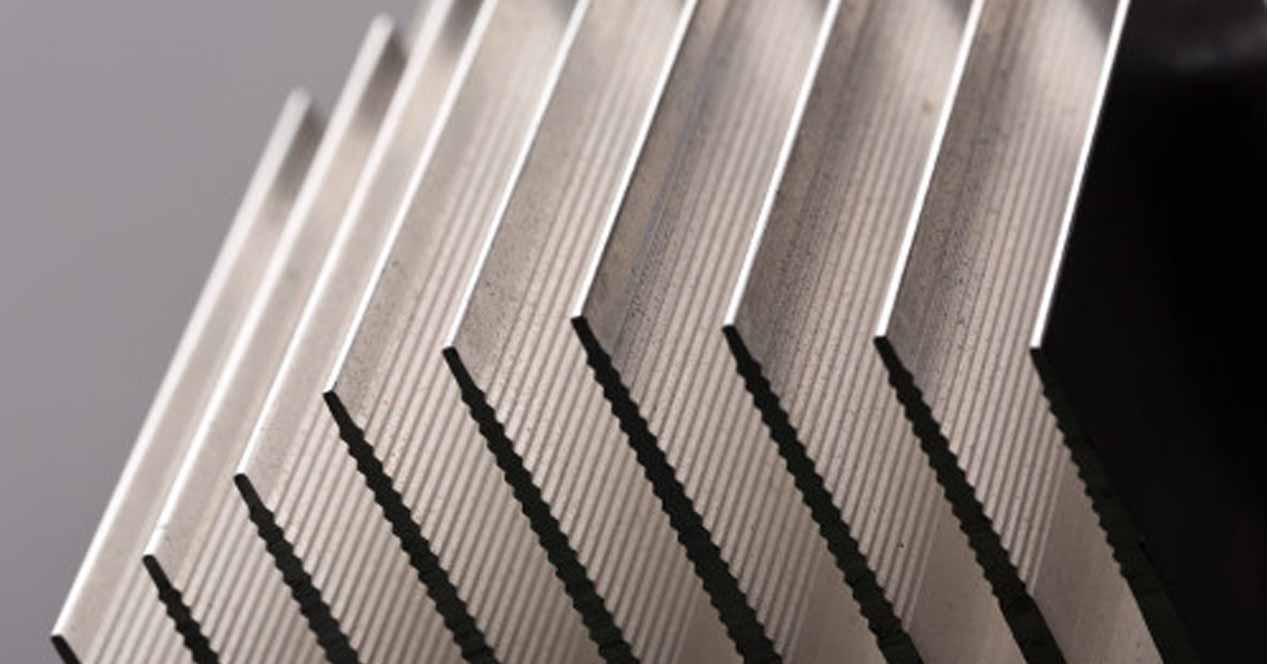

Everything has its pros and cons, but in essence, a heat sink will have better thermal performance with the aluminum fins closer together and a high static pressure fan as this maximizes the heat dissipating area (being closer to each other there are more fins than when they are separate; look for example in the ‘image above where the heatsink barely has 15 fins), while the trade-off is that it will generally be stronger than the one with the fins farther apart (which is why manufacturers tend to use a pitch of fin spacing agreement).

For this reason, it is almost always advisable to use the fans that manufacturers include with their heatsinks, as in theory they should be designed to provide the best performance with the heatsink layout. If, for example, you buy a heat sink with the fins close together and install a fan with high airflow but low static pressure, you will surely perform worse than if you used the one supplied with the product. Therefore, if you intend to use fans that are not the ones supplied with the heatsink, try to check if you need them with more static pressure or with more airflow, which will depend. of the separation of the fins.