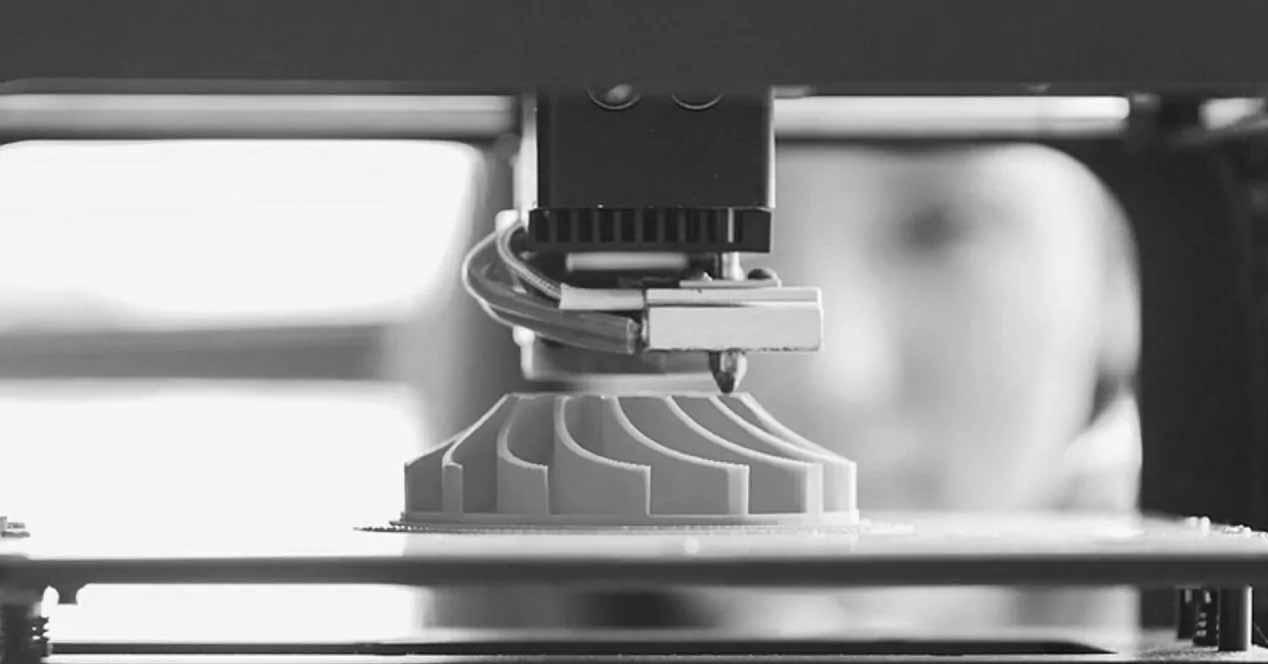

To get the best performance from your FDM 3D printerCalibrating the extruder is something you should be doing sooner or later (in fact, it’s best to do it when it’s new). By doing this, you will make sure that the amount of filament coming out of the nozzle is adequate (not too much, not too little), making sure that your 3D prints are of the right quality, that you are not wasting filament and that it is ‘is the case. not get your head stuck.

The importance of calibrating the extruder

If you’ve ever had trouble getting the first layer to adhere to the surface, or if your prints have smudges, bumps, or gaps, calibrating the printer’s extruder could be the culprit. Too little filament through the extruder will cause the layers are delaminating and cause a poor adhesion of the print to the plate; In addition, too much filament can also result in distorted prints or full of fiber that shouldn’t be there.

On the other hand, a properly calibrated head will provide the good amount of filament in each layer of the print, making the optimal result. This means that the first coat will adhere properly to the build plate and the end result will look exactly as it should (depending of course of the quality and the precision of your 3D printer).

In addition, the extruder calibration It’s a pretty quick and easy way to get a big improvement in the quality of prints, and as you’ll see below, it’s something you can do on your own without too much effort and without tools. complicated. Also, extruder calibration works for both Bowden tubes and direct drive types, so as long as your 3D printer is FDM type, our guide should be helpful.

Finally, it should be noted that the process of calibrating 3D printers is a task that should be performed regularly to ensure that it performs optimally. It is especially important to do this if you start to notice that your prints are warped or spaced, but it is still something that should be done every now and then even if the printer is apparently performing well.

How to calibrate the extruder of your 3D printer

The first thing you need to be clear about are the tools you will need for this calibration process. Obviously and as we have already mentioned, these are FDM 3D printers with direct acting extruder or Bowden tube; Also, you need filament, a Vernier caliber, an indelible marker of a different color from the filament you are using (to be able to see the marks we are going to make) and, of course, a PC with the 3D printing management software. As you can see, the requirements are nothing that almost everyone in their house does not have, except for the size that you will need to purchase.

The first step in this process is to load the filament into the 3D printer. Check your printer’s instruction manual for how, but it should be a straightforward process (in most cases it will heat the nozzle and then feed the filament into the extruder). Once the filament begins to come out of the nozzle, you will know the printer is ready to begin calibration.

Make sure to remove any old material adhering to the tip of the nozzle – ideally it should be as clean as possible before you start the process. In addition, it is important that the nozzle is hot for the calibration to be as accurate as possible.

The next step is connect the PC to the 3D printer, And for most printers, you can do this via USB. Once you have connected and configured it, you need to put the printer in Relative mode

Next, you will need to measure and mark the filament that we intend to extrude. For this example, we set the gauge to 120mm and then measured 120mm of filament from the extruder inlet (or from the filament outlet sensor, depending on the printer). You need to use the permanent marker to make a small mark on the filament with this measurement, and make sure it is visible and as precise as possible (so do it with patience and lots of pulse).

Once you have marked 120mm on the filament, use the terminal to send 100mm of filament through the extruder; To do this, enter the command in the terminal G1 E100 F100, and the printer should immediately start extruding what it “thinks” is 100mm of filament through its nozzle (this process will take about a minute).

Now using the gauge again, measure the distance from the extruder or sensor inlet to the mark you made on the filament. As we made the mark at 120mm and in theory we used 100mm of filament, we should only have a 20mm difference; If the measurement is exactly 20mm, you don’t need to calibrate anything because everything is correct, but if the distance is more or less than 20mm, then you need to calibrate the extruder.

To adjust the extruder, you will need to perform some calculations; to start, you will need to find the current value of steps / mm of the printer, and to determine this value you will have to send the command M503 via the terminal.

This should return you a few lines of code as you can see in the screenshot above. Find the line titled “echo M92 […]»And at the end of that line you will find a value, which indicates the steps per mm of the printer.

Then you will need to find the value of the physical steps / mm, and this is precisely the measurement you took before. Suppose this measurement is 22mm, which would give 98mm of worn filament. Now you need to calculate how many steps it took for the extruder to get this measurement of filament, and for that use the E value we took in the previous step multiplied by 100 (because we have removed 100mm of filament, remember).

If the extruder E value was 417.30 as in the example, then we would have 41,730 steps to reach 98mm of extruded filament. The final calculation needed is the correct number of passes to extrude 100mm of filament, and to get this value just divide the number of extruder passes by the actual mm of extruded filament. Following our example, we would divide 41 730 by 98, which is equivalent to 425.81 steps / mm, and this is the value that we will now have to enter into the printer (replacing the 417.30 that it a) to calibrate it.

The last step to finish calibrating your 3D printer is to set the E value with the correct steps we calculated. To do this, send the M92 EXXX command to the printer in the terminal, where X is the value in steps / mm that we calculated. In our example, we would write M92 E425.8. Then you need to save the value sent with the M500 command, and we would have it fully calibrated.

At this point, it is advisable to restart the 3D printer so that it loads the new values we have established and restart the initial process (mark 120mm of filament, extrude 100mm and measure) to verify that now the printer takes determining exactly how much filament to remove, no more and no less (otherwise, something went wrong and you should repeat the whole process).