The PC chassis is becoming more and more similar, the race has become more visible and no one wants to leave its rivals. In a few cases we find models that are exactly the same, so any information that may distinguish them is used by the manufacturers.

Attending a dive event at 5.25, we saw the return of the program double room and now we see how windows frames have been reduced to a minimum and in many cases not.

This runs into the problem that screws are needed for repairs and a series of glass bases to accommodate the chassis, leaving large gaps in the dust and no filters in between.

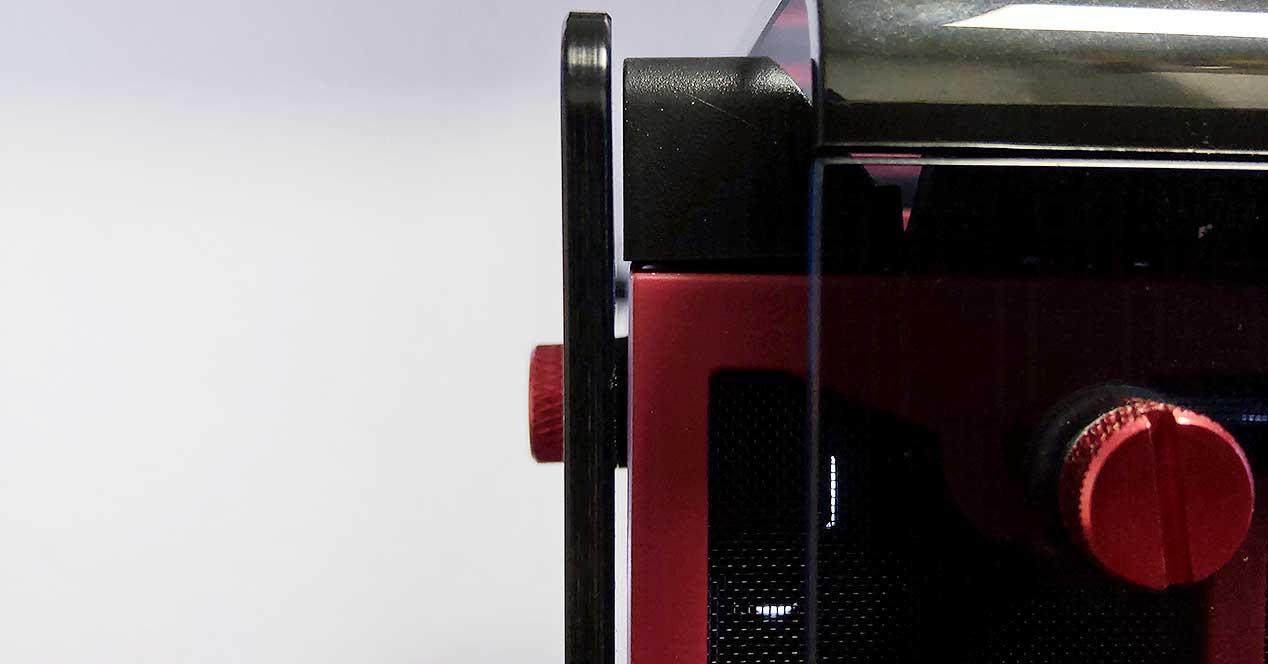

So great is the GAP between the chassis and the glass: the dust is incredibly free

Any surface that reaches the inside of the box should carry some sort of filtering, but this only happens with very high-quality models sometimes and sometimes not. Large brackets or overhead for several fans and their vertical or horizontal alignment. It is the traditional food for the introduction of enemy number 1 of any PC: dust.

The fashion of flawless crystals leaves this dangerous thing to roam freely on our PCs, so let's try to put the brakes on it with affordable, easy-to-use and elegant solutions.

The first thing we will need to know is the distance from the chassis profile to the warm glass window, as this will give us the height of what we will buy. We should try to be as transparent as possible, because some elements we will show yield without a problem, but for some producers are somewhat difficult and it is not a matter of forcing glass closures.

Once we have this dimension on the four sides of the receiver (front and back need not be equal) we will measure the distance we need to cover the tower profile. In some models it can be screwed to break and in others it should be the chassis profile itself.

This is a matter of preference or need, because in some it is a very good look in one place and in some chassis in another. Usually, each side of the square that includes the glass will have different height and height, so we have to use different methods.

Print rubber, the best solution in terms of price, aesthetics and ease of use

Our recommendation is undoubtedly the professional profile profiles. In some cases it is not easy to find them, since some hardware stores do not have them, and in that case you will need to find one or more similar industrial installation companies.

The best quality comes from EPDM, that is, ethylene propylene diene injection, an elastomer with good abrasion resistance and coating, where it also emits electricity and is used in the automotive industry as an integrated sealant and waterproofing agent.

As we say, it is the part that can be difficult to find as it is industrial as a general rule, but it is useful because it is flexible and has the right PC parts, in addition, it is sold either in rolls or in meters and is very cheap.

The only thing we will need to do is buy the required length and dimensions and turn it into a chassis profile while maintaining the precision of the rubber, as simple as that.

For this, we will make a type of duct to protect the air from entering or leaving and thanks to the fact that dust will always be stored outside the cabin, making air vents through the small openings around the tower (hard to cover in most cases) but most of all, dust filters, which will stop this enemy.