The composition, shape, conductivity, and quality of thermal pads greatly affect not only the performance of a graphics card, but also its durability or useful life. When choosing these components, the manufacturer should also take into account something as irreverent as the curvature of the GPU chip itself, the PCB, or the heat sink, and this is something that they don’t seem to think of. take into account precisely.

Why are there temperature issues on the NVIDIA RTX?

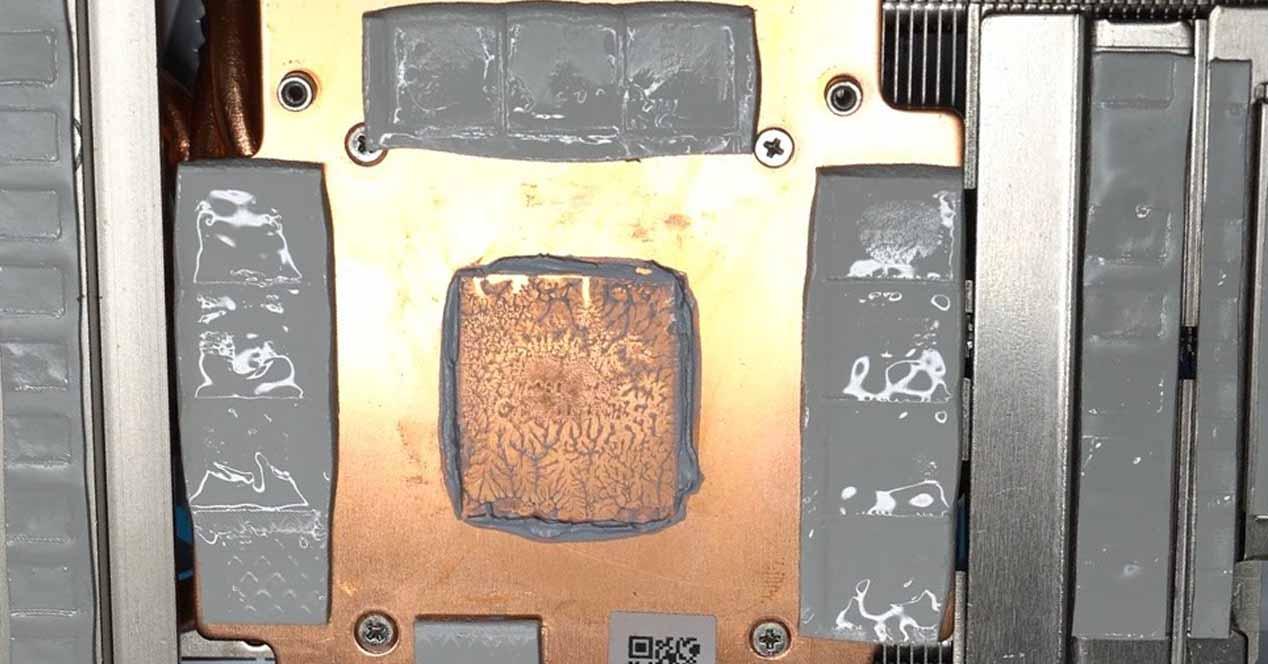

NVIDIA’s larger Ampere architecture chips are quite distorted, and we’ve talked about this in the past. Concave curvature was already present in Turing, but not as extreme as it is today and the overall height of the package w as also much more uniform. To test this, if measured with a special device (which displays the ratio you see above) at 20º C, the die curvature remains at 0.068mm (according to NVIDIA, in specs), a value that matches is within the tolerable range but depends on the model, as 0.08mm has been measured in some.

This can still be handled fairly well with thermal grease if it isn’t too runny, but there comes an extreme where the gap is too big and the thermal grease just isn’t enough to fill the gap and so that the heat transfer takes place smoothly. .

At the same time, if you scan the dimensions accurately and output a 3D graph, you can see that in many places the die curvature is 0.08mm or even more, which certainly raises questions about the way such a thing can happen. Often the whole board (including the die set) is already deformed at the factory and deviations of up to 0.156mm can be seen in some parts.

The packaging has certain constraints and height tolerances, so this is still quite normal. However, NVIDIA specifies a tolerance range of up to 0.3mm, which is very high compared to Turing.

The following evaluation of the height differences shows simultaneous swelling and deviation from the actually measured heights of the 3D file we mentioned earlier. You can also see the flex of the pack and the underlying graphics card board very well, and in this case we see that even the PCB had to bend considerably due to the screwing in to make contact.

So we’re seeing a deviation of around 0.3mm from the norm, which NVIDIA sees as the limit in its RTX graphics but is still workable for thermal paste according to them. These 0.3mm don’t seem like much at first, but in practice you will have big problems transmitting heat.

So these deviations and tolerances lead you to have to resort to thermal cushions to transmit heat, and this also explains why they get thicker and softer. The 1mm thick thermal pads are then converted to products up to 2mm, with greater thermal resistance and poorer performance, but which at least “reach” from one place to another to cover the space and be able to transmit heat.

All of this brings us to the fact that manufacturers choose thermal pads that are much thicker than normal so that they can cover all those big gaps, but also softer than normal so that they don’t put too much pressure in the less concave areas. And this is precisely where the temperature problems in the NVIDIA RTX come from.

The problem concerns all manufacturers

At first glance, these issues don’t just stem from NVIDIA RTX benchmark GPUs, they affect all or almost all manufacturers. Basically due to the curvature and imperfections of the NVIDIA chips they were forced to use thicker and softer thermal pads

In fact, the problems go further. In the images that we have placed above and below these lines, we can see the carelessness with which thermal pads are handled during assembly. In the image above, from an AORUS RTX 3080, we can see that the capacitors are exerting extreme pressure on the thermal pad and the thermal pad is in fact bent and the last capacitor is not in contact. In the image below, corresponding to a PowerColor GPU, we can see that they have not even removed the protective plastics (even if we see that they wrote “Remove before use”, remove before use) .

At this point, one can only ask manufacturers to regain some traction and care more about the quality of their products. It is not admissible to pay 1000 dollars for a graphics card and run into serious temperature problems that affect its consumption, noise and performance because the manufacturer did not bother to remove the gaskets from the thermal pads.

Less RGB and more quality under the hood, please.