As you surely know, the new Intel Alder Lake processors have not arrived on the market without problems. We are not talking about the stock of its models or the DDR5 itself, but about the temperature problems, which we have already talked about in previous articles and a partial solution has been seen. Now a new “trick” or mod (whatever you want to call it) further fixes the flaw that these processors have built in. How come? Fix flex issues on Intel Core 12 processors?

All this has to do with the pressure exerted by what is now called ILM o Independent Loading Mechanism, which is the part where the docking mechanism exerts vertical downward pressure on the processor so that it touches the pins. The IHS are logically prepared for such a contact, but since the CPUs are now longer (rectangular), the problems generated have changed and Intel did not count on certain imbalances in said pressure.

Returns flex in CPU, total disaster in Core 12?

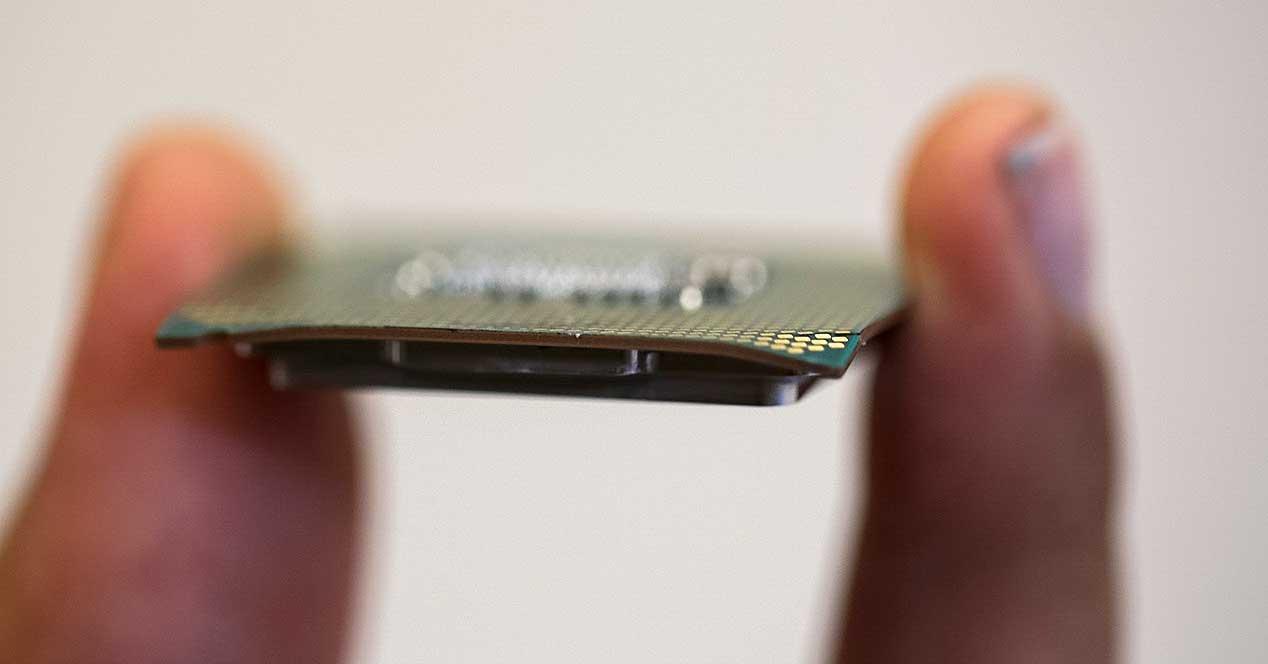

Although many of you won’t believe this and have a server with 10+ years of delid and PCB fix experience, it’s no surprise what happens with Intel Alder Lake processors . There are only two pressure points, longitudinal and far from the points, because, as we mentioned and it can be seen with the naked eye, the CPU is rectangular and not square.

The problem, or rather the problems, are two that interchange and complement each other:

- Welding the die and IHS makes the center of the CPU concave.

- The anchor bends the PCB and increases the concavity effect.

Therefore, and although we already recommend that in the case of heatsinks or blocks with a backplate, this should be installed first and then the CPU to try to avoid this effect as much as possible, the reality is that ‘after a certain time and with thermal differences in cooling and heating of the materials, the stratum ends up yielding as well as the pins.

Alder Lake’s solution to bending

The solution is simple, cheap and easy to apply: spacers on the processor retaining bracket or clamping mechanism. All you have to do is remove the four screws from the anchor and place the washers (preferably nylon) to then reassemble the system. The most obvious question would be how thick? The comparison is not in vain since four different measures were tested: 0.5mm, 0.8mm, 1mm and 1.3mm. The result? Come and see:

The pressure exerted by the retention system on the CPU is so high that with only 0.5 mm we already gain almost three degrees, with 0.8 millimeters

Esto evidence lo que ya sabíamos: las CPU Intel no logran un buen contacto con cold plates o blocs de refrigeración, algo que antes no pasaba sino que simplye no era un contacto óptimo porque era precisely el centro el que terminaba por tocar dejando a la periferia “in the air”.

In short, at Alder Lake it is more optimal to place the nylon entry washers before placing the heat sink to improve contact by reducing anchor pressure. It’s also up in the air if Core 12 flex at the anchor manufacturer (Foxconn, Lotes etc.) or if it’s an Intel design issue. Didn’t they take into account the thermal cycles and their influence on the support? Didn’t they realize that the pressure exerted was more than necessary to ensure contact between the pins and the PCB as well as between the cold plate and the IHS? We will probably never know…