The word HAMR comes from the acronym of Heat assisted magnetic recording, or heat-assisted magnetic recording, and as the name suggests, it is based on the ancient principle of magnetic recording which has been used since the 1970s in storage devices as we know them, but nevertheless now promises that the amount of data that can be stored on a magnetic device will be considerably increased; a current “ standard ” hard drive is capable of storing around 1.14 TB per square inch, while with HAMR this density is increased to 6 TB / in2, potentially reaching up to 80TB capacity with current technology.

Let’s see how it works.

How does HAMR technology work?

In the following illustration, each region represents a bit where the colors can be 1 and the whites can be 0, because as you know this system works with a binary information system. Normally, some of these regions become congested (magnetic orientation) leaving unnecessary space that cannot be used. To improve information density, HAMR uses heat to help control these regions and reduce anisotropy (this is the difficulty required to change magnetic orientation).

The first hard drive to exist used longitudinal recording (LR), which placed the magnetization in the same plane as the disc. The field we are writing with is the marginal field, where the deep field deviation is filtered out (see illustration).

As we increase the density of the area and reduce the size of the regions or “grains” where it is written, it was necessary to increase the anisotropy of the support and, however, as the support becomes more stable, writing becomes more difficult and A larger field is needed to reliably change the direction of the grains in the middle and save the data. For 60 years, the field has been increasing from the magnetic recording head, but eventually its natural limit was reached, it was not enough for more.

To build a device with HAMR technology, they had to make the following changes:

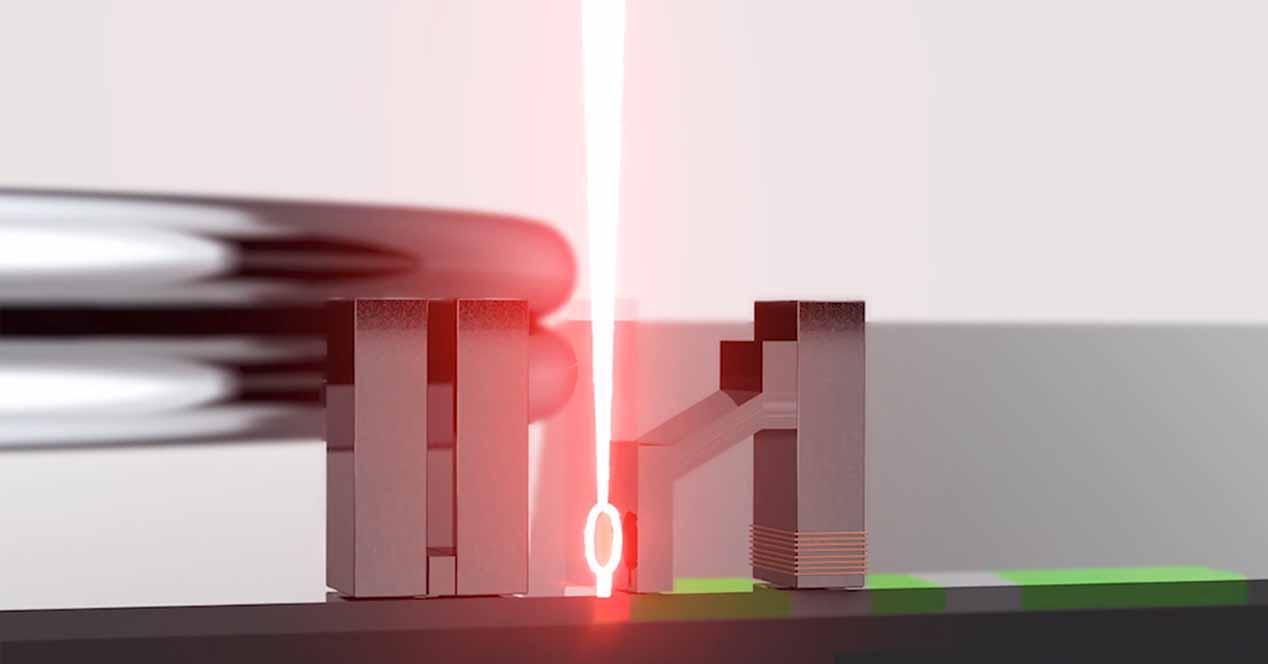

- Add a laser diode to the head.

- Develop an optical path to direct laser light to the NFT.

- Integrate the NFT into the recording head.

- Develop new media compatible with HAMR.

- Change the firmware of the unit.

- Adjust the manufacturing process.

- A million small details that engineers have spent countless hours working on.

From PMR to SMR and finally, HAMR

Using Perpendicular Magnetic Recording (PMR), it was possible to add a smooth base coat to the medium and place the medium in the leading “hole”, where the field is greatest and where every bit is. perpendicular to the heads. media rather than the entire surface. The next evolutionary step was to design Magnetic Shingle Recording (SMR), which achieves greater surface area and density by “compressing” the data tracks rather than reducing the size. bits. The tracks overlap, like tiles on a roof, allowing more data to be written to the same space.

As the read element of the drive head is smaller than the burner, all data can be read on the truncated track without problem and without compromising data integrity. In addition, SMR does not require a significant investment for its development, which makes it possible to implement hard disks with this technology while maintaining a low manufacturing cost.

On its own, SMR has already delivered a 25% improvement in hard drive capacity with its introduction in 2014, but that was not enough and they also found that PMR was approaching the limits of storage technology. High anisotropy iron-platinum (FePt) media can overcome thermal stability issues with traditional PRM media and high surface densities, but with conventional recording media you quickly run out of field to write.

This is where HAMR technology comes in, as it allows you to bypass this limitation by literally heating the medium. At room temperature, the middle grains are small and thermally stable, exactly what we need, but heating them can temporarily reduce the coercivity of the medium.

So in summary with HARM what you do is the data is stored at room temperature but before writing the media is heated to reduce its coercivity then it is cooled again, all in less than 1 nanosecond. According to manufacturers, HARM technology allows you to expand the density from 1 to 5 TB for every square inch of area.