Some analysts have, in fact, said that demand for chips exceeds the 30% production capacityGiven the zero responsiveness of major manufacturers to this sudden surge in demand, the chip shortage is expected to prevail through 2022.

Demand for chips is on the rise

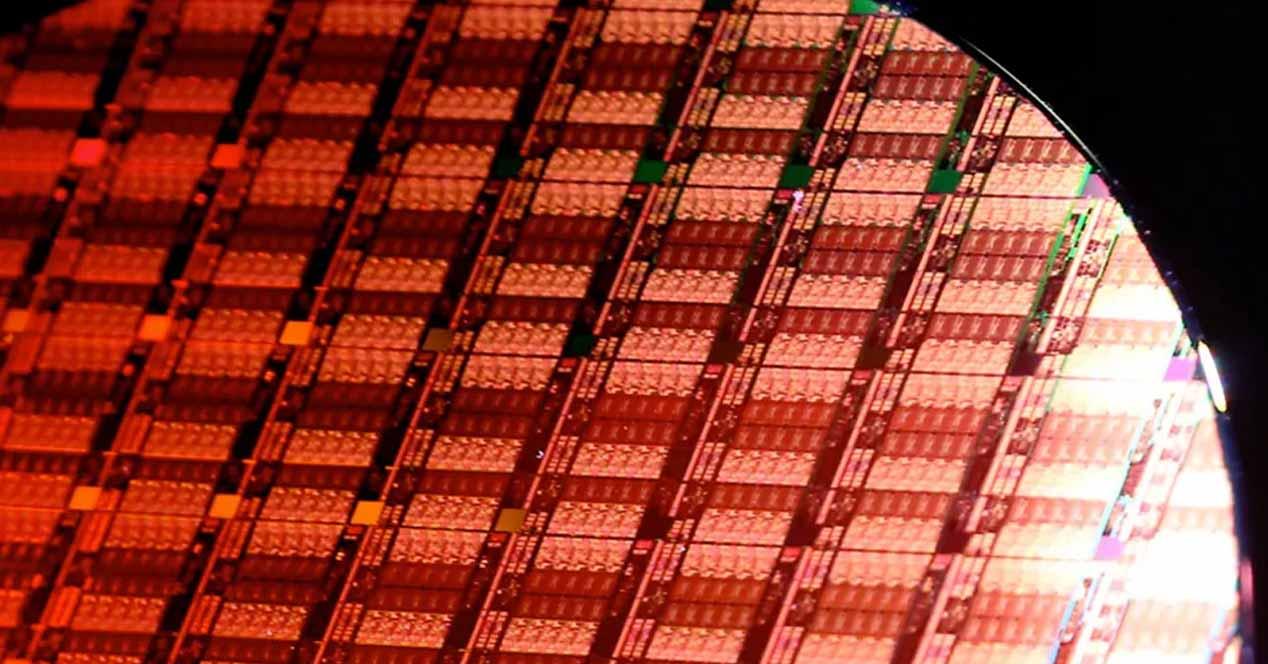

Today, virtually all electronic devices have chips, so the demand for semiconductors is at an all time high. In addition, these chips are becoming more and more complex (i.e. more difficult to manufacture) and the number of chips per device is increasing. Over the past year, several additional factors have increased demand for chips to levels far beyond what the industry can offer.

First, people started buying more desktops, laptops, and other electronic devices including consoles, TVs, smart devices, etc. due to the transition to telecommuting and distance learning, in large part because they are spending more time at home due to the pandemic. Second, the existing production capacity (the number of chips that could be produced) barely met demand in 2018 and 2019, and was already showing that it could not meet demand in 2020 and 2021.

It is noteworthy that Intel faced huge demand for its products in 2018 and has already taken the relevant steps to avoid the chip shortage while the rest of the industry has done nothing even though it has saw the looming avalanche. As a result, the world is now facing severe semiconductor manufacturing capacity shortages and chip packaging issues.

Third, there is the trade war between the United States and China, which has caused companies to purchase large quantities of semiconductors in advance to store inventory, which has increased pressure on the supply chain. supply.

Supply chain is 30% lower than demand

Due to this strong demand for chips, shares of semiconductor companies have exploded in recent quarters as they beat all analysts’ expectations and their own revenue forecasts.

“We believe semiconductor companies are shipping 10-30% below current demand levels and that it will take at least an additional 3-4 quarters for supply to catch up with demand, then an additional 1-2 quarters to to replenish the stocks of customers and distribution channels and thus return to normal levels ”.-

JP Morgan analyst Harlan Sur said.

According to Christopher Rolland, analyst at Susquehanna International Group, lead times for semiconductors currently exceed 14 weeks (over 3.5 months), which exceeds the cycle time of the most complex process technologies. Rolland says the situation will get worse this spring after countries lift lockdowns and economies restart.

“We don’t see any major correction on the horizon, given ongoing supply constraints, as well as continued optimism about improving demand in 2021. We remain more concerned about the continued disruption in the market. supply and rising costs of power supplies. correction of stocks for several quarters ”.- said Matthew Sheerin, analyst at Stifel.

The shortage of chips will persist for some time

Major foundries, including those of TSMC and GlobalFoundries, have announced expansion plans for this year and there are signs that packaging companies will follow suit. However, companies such as ASML, Applied Materials, KLA, LAM Research and others will take months to create the tools needed for new factories, and to that must be added the time it will take to install the new equipment and the activate. . As a result, capacity decisions made now will have no impact for several quarters in the future, and that’s better.

With demand already outstripping supply by around 30% and backlogs for many products keep piling up, it will be months after semiconductor companies resolve their capacity issues. before everyone gets the chips. What do you need? Meanwhile, it is unclear what happens to the “excess” capacity once demand is satisfied and inventory levels return to normal.

Additionally, it is clear that it remains to be seen whether non-factory chipmakers will continue to introduce new models if demand for existing chips cannot be met. In other words, if for example AMD and NVIDIA are already having problems with their new generation of graphics, the next generation is very likely to suffer a considerable delay.