If we had to choose a point where the manufacturers do not hesitate to reduce costs, it is undoubtedly the cooling of the components, not in vain, we have already seen more than once how the use of better thought out solutions and better performing ended up being top notch. This goes to show that in PC components, this is something that many manufacturers overlook, as they expect the end user to do the buying and choosing of said materials.

Liquid metal as coolant? How is it possible?

The idea is none other than to use a type of metal to evacuate the heat from the chip. Mercury surely came to mind in your imagination, however, its fumes are poisonous enough to send you down the hole in no time. So gallium is used, a type of metal that at room temperature has a boiling point much higher than the hottest of your chips will ever reach.

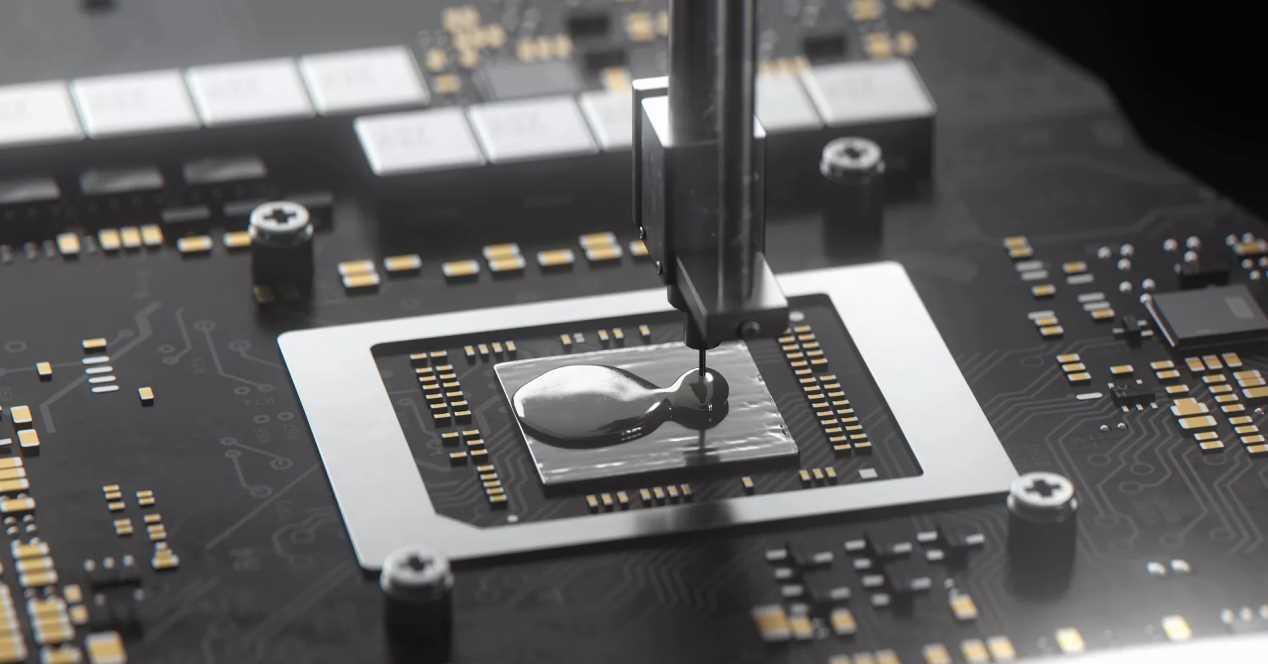

It is impossible for gallium to be a thermal paste in school as many say, because physically it is like a metallic butter and it does not liquefy even more when it reaches temperatures above 100º C. Of course, if you have the chip vertical to the ground and the thermal paste is not well insulated, then it can happen that being a metal, when it comes into contact with the plate it creates problems on the device. Let’s not forget that like any metal, a thermal paste based on liquid metal is also electrically conductive.

Is it better than regular thermal paste?

Well yes, since it can dissipate much more heat and therefore it will prevent your computer components from reaching high temperatures. In numbers, the best conventional thermal pastes have a dissipation capacity of 15 watts per meter-kelvin, while gallium-based thermal paste reaches 73 watts per meter-kelvin.

It is therefore ideal in systems with a small chip with which we want to achieve a high clock speed in a stable and smooth way. Hence its use in ultralight laptops. However, it is difficult to apply and requires great care or specialized fixtures where it is totally encapsulated. Also, in many systems, in order not to break the security seal, it is recommended not to disassemble the processor and heatsink encapsulation.

A different case is that you are going to do it yourself, in this case you can apply it like a classic thermal paste, but you will have to be very careful when applying it and not overdo it. If you are clumsy, we advise you to call a specialist to apply it to your PC’s processor.

Why is it little used if it is better?

There are several reasons for this, but mainly because of its behavior with other metals which are often used to encapsulate certain chips. For example, it is not recommended for use with aluminum as the two metals eventually combine and create an alloy with an oxide layer in the process. This layer, if not large enough, will create an exothermic reaction generating a large amount of heat. This is why combining liquid metal thermal paste with an aluminum heatsink is not a good idea.

Most heatsinks are made of aluminum, as it is more common and easier to find than copper, which gallium works with without any problems. The problem is that in many cases this means additional cost and that is why many graphics card manufacturers, in order to save on cost, end up using heatsinks or aluminum heatsinks.